Some knowledge points of the remaining heat recovery of the boiler, the well heating manufacturer tells you

Release Time:

2022-08-12

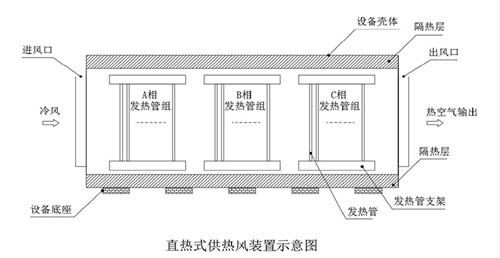

The well entrance heating manufacturer believes that the waste heat recovery of the boiler is a device that recovers excess heat energy. It is very convenient to use, energy saving and environmental protection. There are many types of boiler waste heat recovery, and different types of boiler waste heat recovery has different effects. So what are the principles and characteristics of the remaining heat recovery of boiler?

The well entrance heating manufacturer believes that the waste heat recovery of the boiler is a device that recovers excess heat energy. It is very convenient to use, energy saving and environmental protection. There are many types of boiler waste heat recovery, and different types of boiler waste heat recovery has different effects. So what are the principles and characteristics of the remaining heat recovery of boiler?

Wellhead heating manufacturers believe that boiler waste heat recovery is the recovery and utilization of waste heat, which is one of the direct and economic means to improve energy utilization, reduce production costs, and protect the environment. The exhaust gas temperature of a boiler directly affects the economy of the boiler unit and the safety of the tail heating surface. Choosing a lower exhaust gas temperature can reduce the exhaust gas loss of the boiler, improve the thermal efficiency of the boiler, and save energy and operating costs of the boiler. However, as the exhaust gas temperature decreases, the heat transfer temperature and pressure of the flue gas and working medium on the tail heating surface decrease, the heat transfer area increases, and metal consumption and initial equipment investment increase. In addition, too low exhaust gas temperature can also cause sulfuric acid vapor to condense in the tail flue, causing corrosion and ash blocking on the low-temperature heating surface. Therefore, the exhaust gas temperature of most boilers is around 200.

Wellhead heating manufacturers believe that the energy-saving principles and characteristics of boiler waste heat recovery are as follows:

1) Product energy-saving principles

Wellhead heating manufacturers believe that the boiler exhaust gas temperature is generally between 120 and 350, and 7% to 25% of the sensible heat and 15% of the latent heat in the flue gas are directly discharged into the atmosphere without utilization. This not only causes a large amount of energy waste, but also exacerbates environmental thermal pollution. On the one hand, the high-efficiency flue gas waste heat recovery device we have designed can not only meet the needs of treating domestic hot water or heating water, but also cool the exhaust gas temperature of the boiler to 100 degrees, significantly improving the working efficiency of the boiler. On the other hand, it has also made due contributions to the national blue sky and white clouds environmental protection cause.

2) Product characteristics of high-efficiency flue gas condenser

1. Advanced: Wellhead heating manufacturers believe that the boiler flue gas waste heat recovery device is an efficient flue gas waste heat recovery device with independent intellectual property rights, citing superconducting heat pipe energy-saving technology; This product is specially designed with a set of condensate discharge device to enable the timely discharge of condensate generated during the condensation process, avoiding secondary evaporation of condensate, and ensuring the recovery efficiency of the waste heat recovery device. The system has obtained a national patent;

2. Energy saving: Using new heat exchange fins, heat exchange elements, and condensate discharge structures can fully recover the latent heat in the flue gas, and the exhaust temperature can be reduced to 40 to 80; Low total pressure drop, low power consumption, i.e. low smoke pressure drop, meeting system requirements;

Beauty: The wellhead heating manufacturer believes that due to the use of efficient heat exchange elements and reasonable structural configuration, the product is light in weight, small in size, and beautiful in appearance;

4. Durability: The heat exchange tubes of the Gongjian series gas fired boiler flue gas condensers are made of stainless steel, with efficient anti-corrosion performance. Thermal stress, corrosion resistance, and strength are fully considered during equipment manufacturing to ensure the safety, reliability, and stability of the equipment.

5. Saving money: Wellhead heating manufacturers believe that the investment cost of installing this equipment can be recovered within one to two years, and after two years, energy saving benefits can be achieved, which can bring significant economic benefits to users;

6. Noise reduction: Due to the special structure of the boiler flue gas waste heat recovery device, it can effectively reduce the emission noise of the boiler flue gas;

7. Environmental protection: Wellhead heating manufacturers believe that part of the water vapor in the flue gas becomes condensed water, which can partially dissolve harmful gases such as NOx in the flue gas and reduce the harmful gases discharged into the atmosphere.

Related News